Efficiency in electronics manufacturing has evolved dramatically over the years, with technology providing innovative tools to streamline processes, reduce waste, and increase productivity. In this article, we will explore some key tools that have been transforming the landscape of electronics manufacturing. These advancements significantly contribute to the optimization of various operations and ultimately improve the competitive edge of businesses in this rapidly growing industry. Keep reading to learn more.

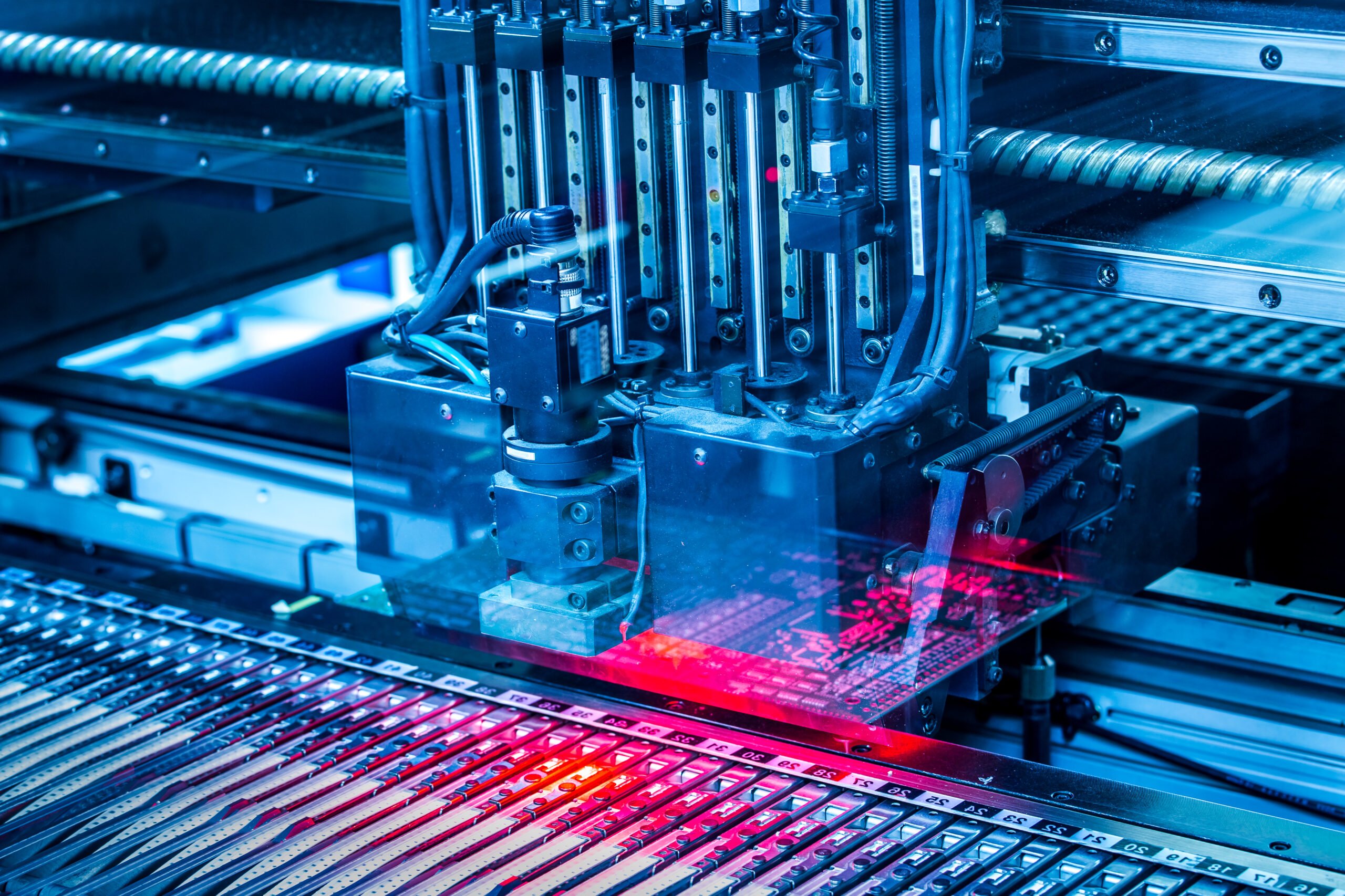

Automation and Robotics

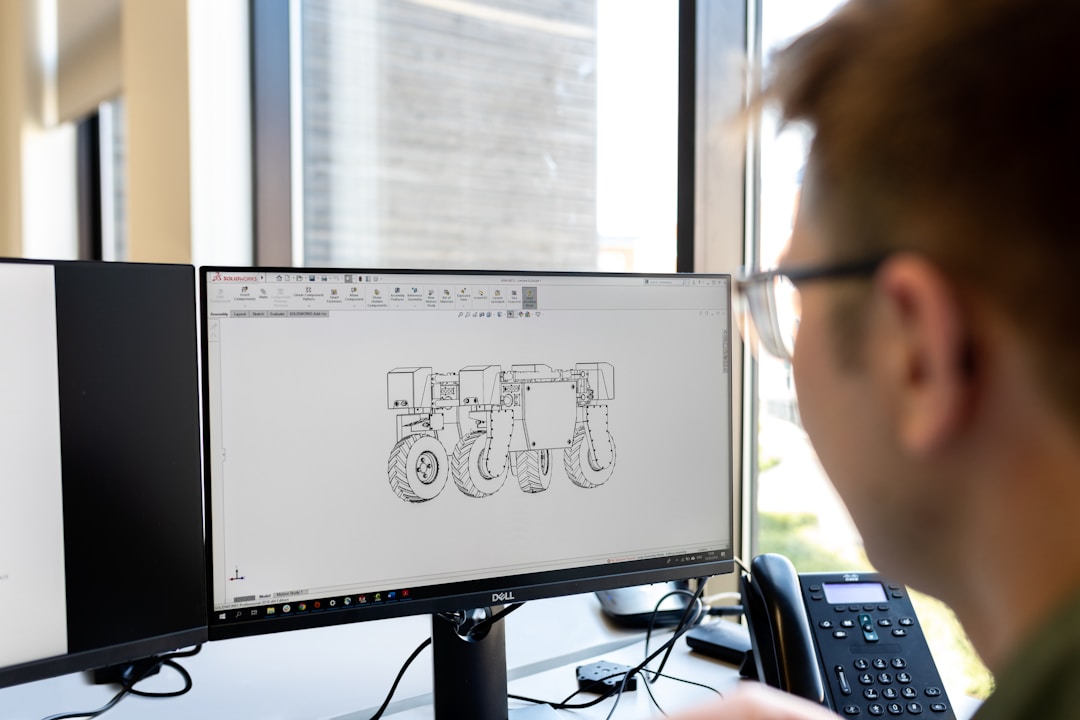

The utilization of automation and robotics in electronics manufacturing has revolutionized the way that products are assembled, tested, and inspected. Through the use of automated machinery and robotic arms, manufacturers can streamline production processes and significantly reduce the occurrence of human errors. This has led to improved production speeds, higher efficiency, and increased reliability in the final products.

Furthermore, automation and robotics have made it possible for electronics manufacturers to achieve precise and consistent results, especially when it comes to assembling smaller and more complex components. The use of these advanced tools has proven to be particularly beneficial for businesses seeking to remain competitive in a market that continually demands miniaturization and greater product complexity.

An equipment sign out sheet can help monitor and maintain these valuable assets in the manufacturing industry. The sign-out sheet essentially helps to keep track of the checkout of tools that involve robotics and other valuable electronics.

Energy-Efficient Manufacturing

As energy costs continue to rise and environmental concerns become increasingly crucial, electronics manufacturers are focusing on finding ways to optimize energy usage in their production processes. By adopting energy-efficient practices and equipment, manufacturers can significantly lower their operating costs and reduce their carbon footprint, benefitting both their bottom line and the environment.

One way that electronics manufacturers can increase energy efficiency is by recovering waste heat generated during production processes and utilizing it to power other operations within the facility. Implementing effective insulation and ventilation systems can also improve energy efficiency, as can upgrading to energy-efficient lighting and machinery. These changes can be more cost-effective when working with a reliable diesel fuel supplier in Saskatchewan.

Real-Time Data Analytics

The ability to monitor, analyze, and respond to real-time data has become increasingly important in the world of electronics manufacturing. By capturing data related to production processes, equipment performance, and resource usage, manufacturers can make more informed decisions and implement improvements to optimize efficiency and reduce waste.

Real-time data analytics can also help electronics manufacturers identify trends and patterns related to productivity, product quality, and equipment performance. This enables businesses to pinpoint areas that may be underperforming, address potential bottlenecks, and improve overall efficiency across the manufacturing floor. As a result, real-time data analytics can lead to significant cost savings and increased competitive advantage.

3D Printing and Additive Manufacturing

3D printing and additive manufacturing technology has revolutionized the way electronic components are produced, enabling faster prototyping and the ability to create complex geometric shapes and structures that may have been impossible or expensive to produce using traditional methods. This technology has led to faster time to market for new products and provides electronics manufacturers with greater flexibility in product design.

By using 3D printing and additive manufacturing, companies can reduce the need for multiple production steps, streamlining the overall manufacturing process. This technology also enables manufacturers to produce small batches of electronic components, lowering the cost of production and reducing the need for large inventories of pre-manufactured parts.

Altogether, the advancements in automation, real-time data analytics, 3D printing, additive manufacturing, and energy-efficient practices have revolutionized the efficiency of electronics manufacturing. By adopting these tools and technologies, electronics manufacturers can streamline their operations, improve product quality, and demonstrate their commitment to sustainability, all while reducing costs and maintaining a competitive edge in the industry.